1. Product Overview and Features

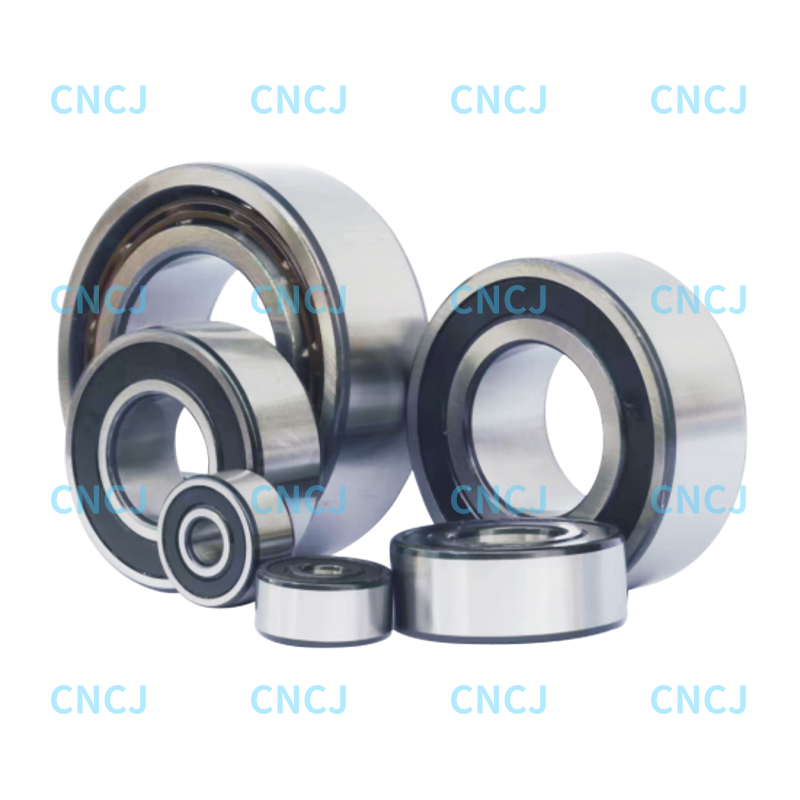

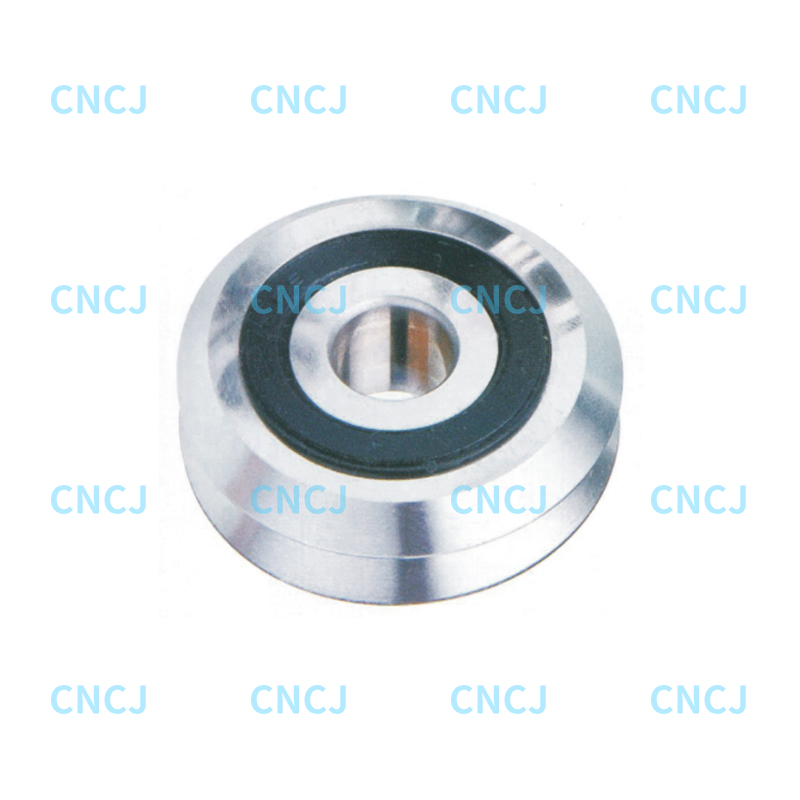

W Series Line Track Rollers Bearing is a mechanical element designed for high-precision linear motion. It uses an optimized roller structure to achieve smooth, low-friction linear motion on the guide rail system. This series of bearings has the following outstanding features:

Precision roller design:

Adopt high-precision bearing steel rollers with special hardening treatment on the surface (hardness HRC58-62)

Toleransi diameter roller dikawal dalam ± 0.005mm

Optimized profile design ensures optimal contact with the guide rail

Low friction performance:

Rolling friction coefficient is as low as 0.001-0.003

Compared with the traditional slider structure, the running resistance is reduced by more than 60%

High-speed movement (up to 5m/s) can be achieved

High-rigidity structure:

Integrated bearing seat design, rigidity increased by 30%

Boleh menahan beban radial sehingga 5000n

Rintangan impak yang sangat baik, sesuai untuk keadaan beban berat

2. Selection and installation guide

Selection points:

Select roller arrangement according to load type (radial/axial/torque)

Menurut keperluan kelajuan berjalan menentukan kaedah pelinciran (pelinciran minyak/pelinciran minyak)

Consider environmental factors (corrosiveness/cleanliness) to select materials

Choose the appropriate grade according to the accuracy requirements

Langkah berjaga -jaga pemasangan:

The flatness of the guide rail installation reference surface must be ≤0.02mm/m

The bearing seat fixing bolts must be tightened step by step in diagonal order

The preload force should be adjusted to make the running resistance uniform

Fully lubricated before initial operation

3. Maintenance recommendations

Daily maintenance:

Check the lubrication condition every 500 hours

Keluarkan kekotoran dari permukaan kereta api secara berkala

Check the looseness of fasteners

Lubrication management:

Grease lubrication: Replenish grease every 3000 hours

Oil lubrication: Establish a centralized lubrication system

Pelinciran gas minyak disyorkan untuk keadaan berkelajuan tinggi

Penilaian Kehidupan:

Pantau perubahan bunyi operasi

Regularly check the wear of the rollers

Consider replacement when the operating accuracy drops by 20%